Tech Etch manufactures metal parts of all shapes and sizes. We use a process that combines photo etching for blanking with universal tooling for forming. This allows us to create intricate, burr-free pieces featuring complex designs.

Our process also makes it easy to prove a product for our clients before moving into the production of large quantities. That way, you don’t have to commit to your current design before seeing a sample of your product.

This guide provides detailed information on practical methods to assure proper function of your product at the best cost.

- Save money by proving your design in pre-production quantities

- Create burr-free parts in complex and detailed shapes

- Get ½-depth etching for hand forming on applications such as board-level shielding

- Add heat shielding for elevated spring qualities

Speak with our team today to learn more about our photo-etching for blanking processes and to place an order.

If your metal parts don’t require structural strength but do require a sharp internal radius, depth-etched bend lines can be used for hand forming. This is a common need for board-level shielding applications.

The lines are created by cutting a groove along the bend line of the metal part. As this process doesn’t require forming tools, the cost of production is lowered.

During the forming process, we take care to design the proper bend radii. Larger radii can withstand a larger deflection without any issues. See the examples to learn more about bend radii and their stress concentration.

Formed angles and offset tolerances are shown in the image below. Speak with our factory team if tighter tolerances are needed for your product.

Our team can heat-treat many different materials, such as beryllium copper, to achieve close dimensional control. Heat treatment can enhance the spring qualities of your product by allows greater deflection without compression set and without adding to the material’s stiffness.

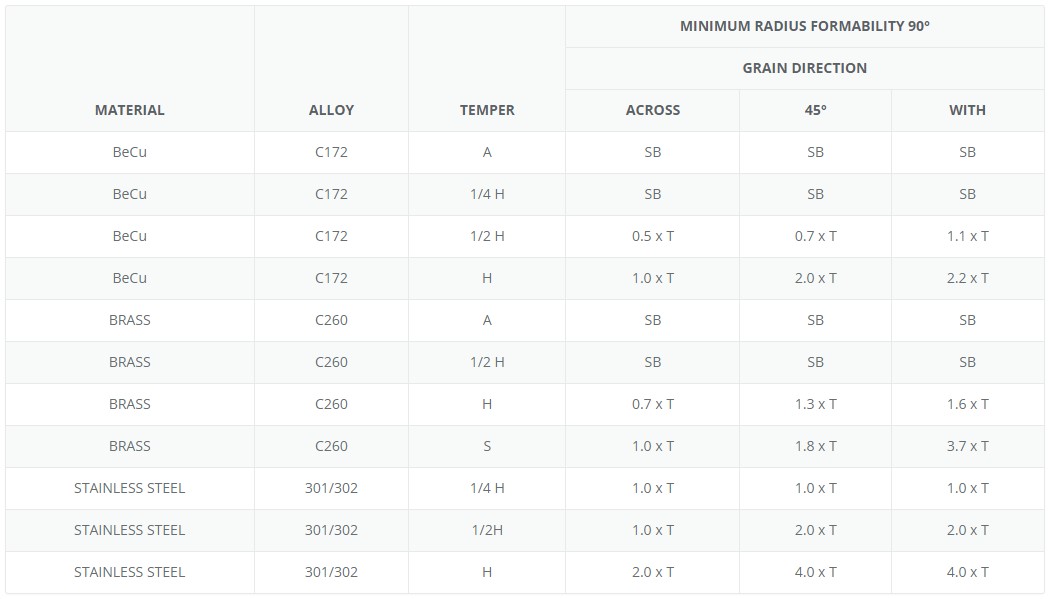

The temper that’s selected for a given bend radius depends on two major factors: material thickness and the bend position with respect to grain direction. The table below shows the suggested minimum bend radii.