Innovating a Better World, One Part at a Time

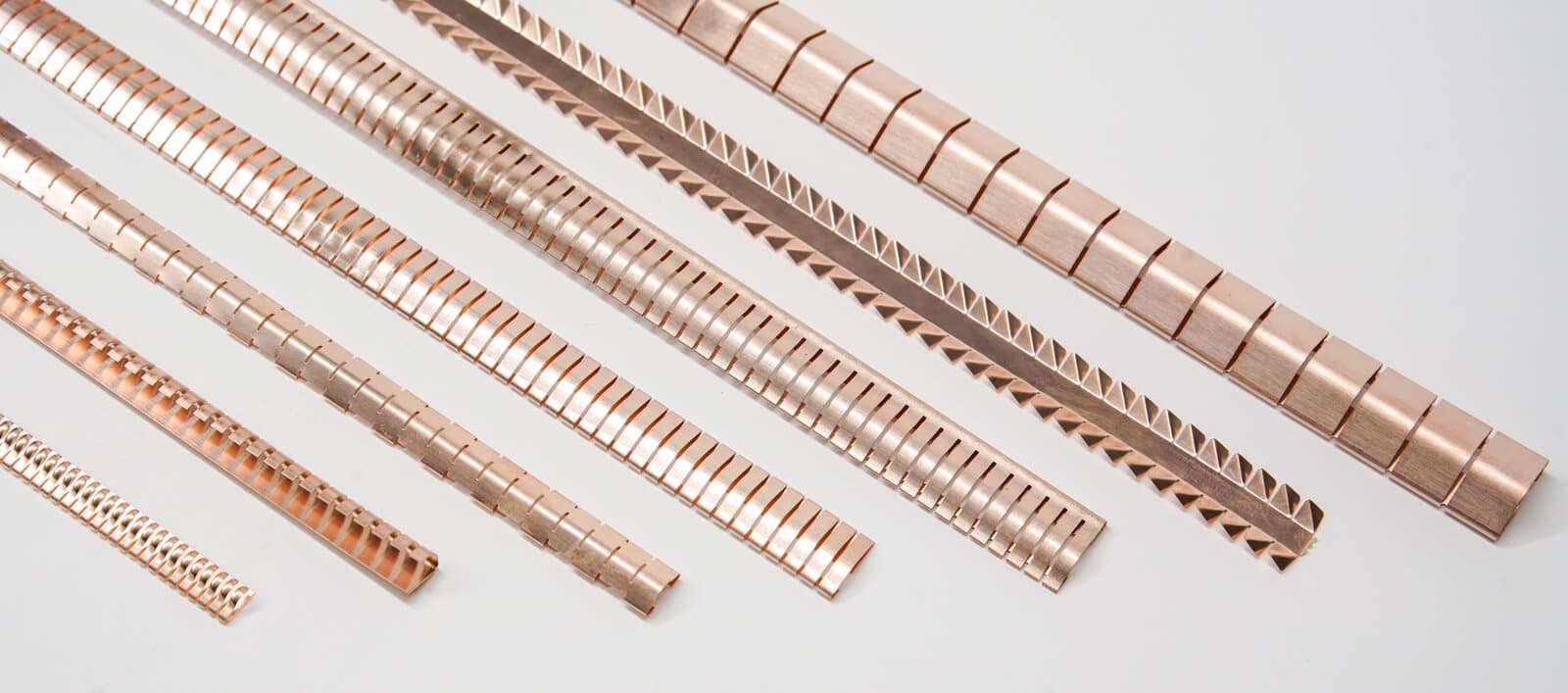

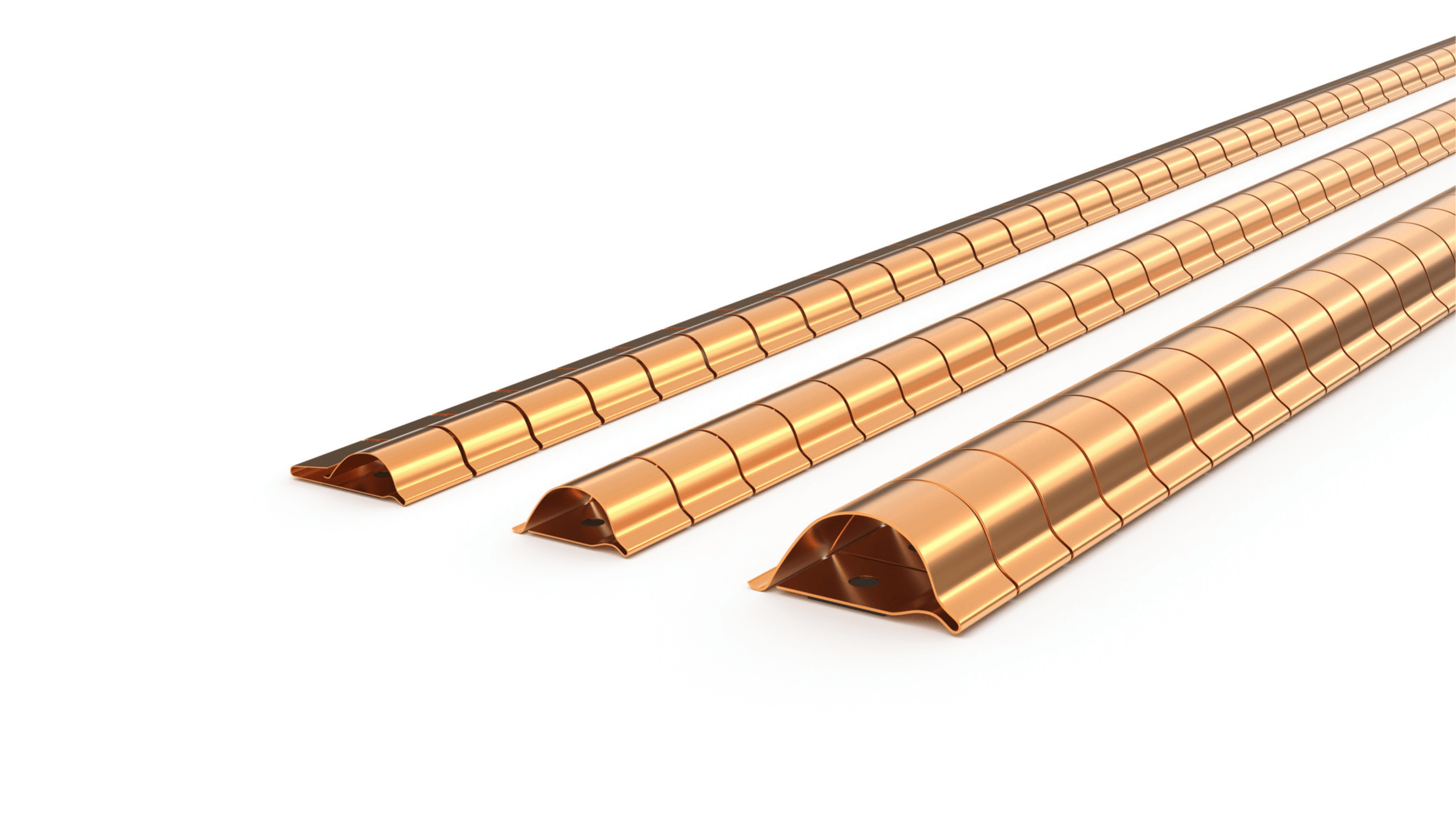

We do this by developing meaningful, long-term partnerships between our employee owners and the industry leaders we serve; and by ensuring unmatched precision, quality, and attention to detail in every project, every time. Our expertise in EMI Shielding, Photo Etched parts, Flex Circuits and Rigid Flex Circuits spans over 61 years bringing experience and expertise to every solution we build.

Company History

Tech Etch started as a small engraving company in Boston, MA in 1964, and has grown through acquisition and new plant construction focusing on specific client needs that look to the future with innovative technologies. We have over six decades of experience and expertise specializing in manufacturing precision-engineered thin metal components, flexible printed circuits, and EMI/RFI shielding, across three locations in the United States (Plymouth, MA, Fall River, MA, and Litchfield, MN).

Tech Etch partners with leading global customers in the aerospace, alternative energy, military, medical, telecommunication, and electronics industries that have highly complex precise designs and demanding regulatory requirements. Our solutions ensure unmatched precision, quality, and attention to detail in every project, every time.

Our mission is to inspire, create, and provide innovative solutions that enhance lives globally.

Tech Etch is known for a variety of solutions and services for nearly every industry out there. We utilize advanced manufacturing processes and work with international distributors to provide clients of all kinds with the parts they need for their businesses. Our team of trained professionals can help you determine the best materials and production methods for your specific products. With our help, you can get the products you need, delivered to your place of business on time and within budget.

Employee Owned

Our commitment to excellence begins with our employee-owners who provide world-class services and innovative comprehensive solutions that enhance lives globally. In 1999, we became an employee-owned business through the Employee Stock Ownership Plan (ESOP) and today, are 100% employee-owned and the 2022 New England ESOP Company of the Year.