Capabilities

Tech Etch manufactures a wide variety of lightweight metal parts as small as .0005” in thickness. We use a photo-etching process that allows us to create intricate and detailed pieces that can’t be made with other processes. This saves on the cost of hard tooling, improves design flexibility, and speeds up production.

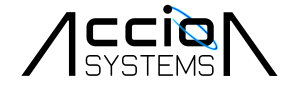

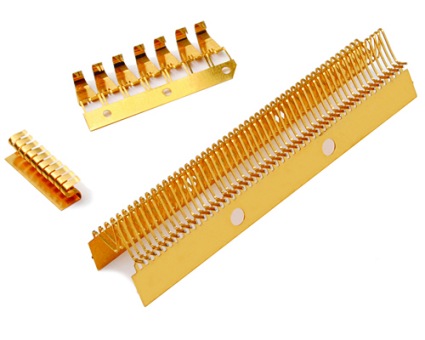

We’re setting the industry standard for the manufacturing of filters, lead frames, springs, covers, heat sinks, shutter blades, plates, shims, and other essential EMI shielding products.

We combine photo-etching with hard tooling to create intricate and detailed metal parts for every application. This allows us to create burr-free parts at a reasonable cost. It also makes it easy to prove your design before creating high quantities of the parts you need.

Our in-house plating and mechanical finishing provides a wide variety of finishes. We offer gold, nickel, electroless nickel, copper, tin, and tin-lead plating, along with solder hot oil reflow. We also offer electropolishing, surface polishing, and vibratory tumbling to ensure a perfect finish. Our masking skills can be used for selective plating, as well.

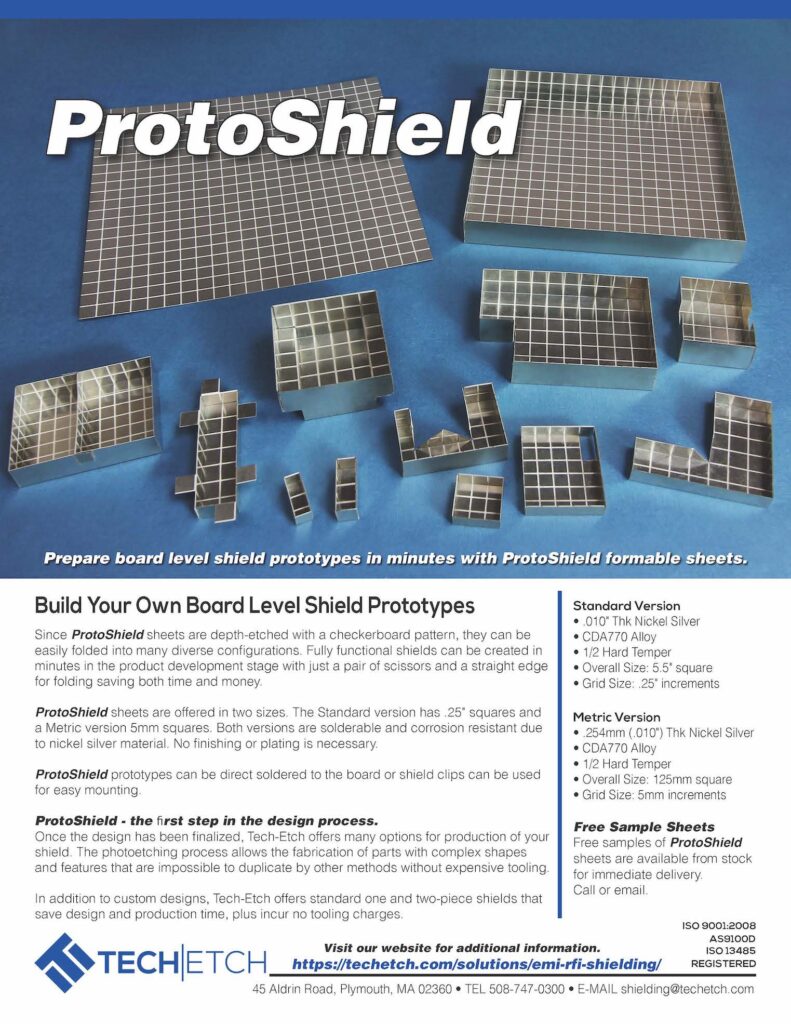

Tech Etch’s laser cutting department can handle any cutting you need performed. From thin materials to thick materials, our 2.5 KW Mitsubishi CO2 Pulse Laser can handle it all. With a high-peak pulse feature, the device can provide dross-free cutting on metals from copper to brass to aluminum and others. Our laser cutting and etching tools also make it possible for us to cut grooves or pockets that only extend partly through the metal.

Tech Etch specializes in photo-etching or photo chemical milling parts from difficult to etch specialty materials, such as Tungsten, Elgiloy, Nitinol, Molybdenum, Titanium and Kapton® (polyimide film), which have material characteristics attractive to the medical industry for implants, springs, cathodes, blades, and stents. Parts can be made from metals as thin as .0005″.

Copper Alloys, Beryllium Copper, Stainless Steels, Aluminum, Nickel and Nickel Alloys, Silver, and Spring Steels, Iron Alloys, Kobar, Inconel,

Photo-etching offers the flexibility of manufacturing prototype quantities and large production runs while maintaining tight tolerance without the high tooling costs and long lead times associated with stamping.

Formed parts are manufactured by combining photo-etching, used for blanking, with inexpensive or universal tooling, used for forming. Heat treatment is available to enhance spring qualities.

At Accion Systems, we have reinvented in-space propulsion for the needs of the New Space industry. The Tech Etch team has been an instrumental supplier in assisting Accion’s Research & Development team to develop cutting edge precision etch & forms from a variety of materials as we develop our next generation TILE engines. Tech Etch has always provided Accion with exceptional service; from project management, engineering support, to quick turn prototype deliveries, Tech Etch’s willingness to bend the boundaries of materials and equipment has been key to our growing partnership as we explore the future of moving in our universe and beyond!