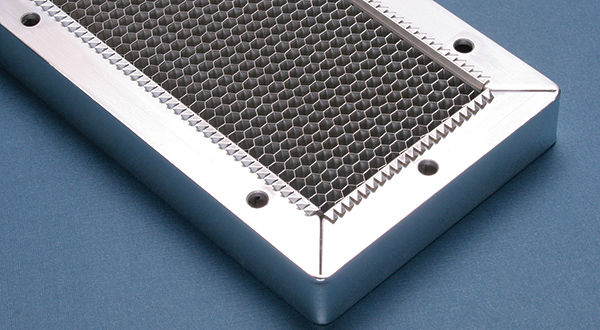

New Gasket Design for EMI shielded Honeycomb Vents Improves Performance and Delivery at a Reduced Cost

Plymouth, MA….Tech-Etch has introduced a new Continuous Integrated Gasket for shielding honeycomb vents that offers better performance, reduced cost and the fastest production time. Continuous lengths of the high-performance BeCu gaskets are mechanically installed under the inner perimeter of the vent’s aluminum extrusion frame. No tooling is required to manufacture and attach the gasket to the honeycomb vents, resulting in reduced cost. After completion, the entire vent system is plated as one piece, so all honeycomb cells, the BeCu integrated gaskets as well as the frame are joined to increase conductivity and shielding effectiveness. The new gaskets are in stock and the efficient mechanical production method has reduced lead times. Tech-Etch manufactures custom and standard EMI shielded honeycomb vents and filters featuring strong, light-weight aluminum frames with various media options. In-house manufacturing and plating support prototype to high volume production while providing fast turnaround. Many RoHS compliant finishes are available.

Click HERE to download a PDF that compares honeycomb vent EMI shielding options.