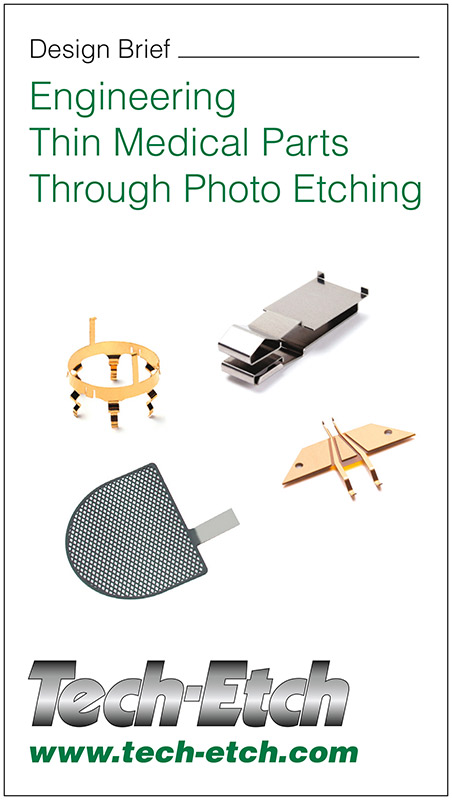

Download Design Brief PDF for Engineering Thin Medical Parts Through Photo Etching

Plymouth, MA….Tech-Etch uses photo etching to produce many medical device component level parts from thin metals. The Design Brief PDF explains the photo etching process, as well as dimensions and thickness tolerances, heat treatment options, and forming and minimum bend radii for various materials. Specialty materials used in medical implants and implantable devices include Nitinol for stents, Titanium for maxillofacial and cranial reconstruction implants, Elgiloy for stiffener bands for valve replacement, Tungsten for battery grids and opaque components for x-ray devices, and Polyimide to produce haptics for intraocular lens implants. Extremely fine MicroEtch screens are produced for medical filters. The 8-page brief describes how the photo etching process provides Tech-Etch the flexibility to produce prototype quantities and large production runs of intricate parts for many diverse medical applications, without the high cost and long lead times of hard tooling. Custom light-gauge parts are produced with intricate patterns, precise tolerances and burr-free edges, in addition to exact repeatability.

Download a copy of our Tech Etch Design Brief (1.1Mb pdf).