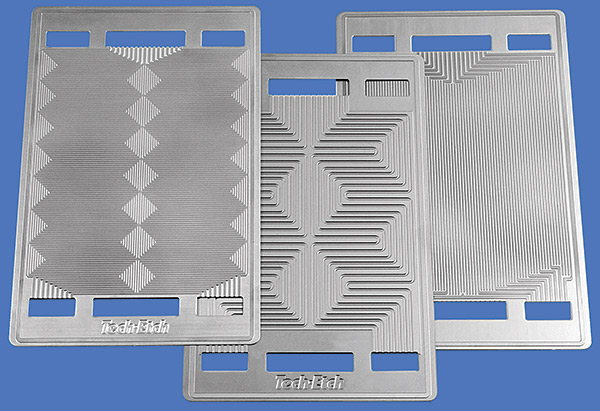

Etched Metal Fuel Cell Flow Plates Offer Superior Electrical Performance

Plymouth, MA….Tech-Etch photoetches fuel cell flow field plates with multiple levels for channels and gaskets. Due to their robustness and improved volumetric power density, extremely corrosion resistant Stainless Steel and Titanium plates offer many advantages over non-metal products such as graphite. These advantages are superior electrical conductivity, heat conductivity, and thinness resulting in a shorter stack. In mobile applications, they are less fragile and able to withstand mechanical impact. In long-life applications they provide extended life times plus improved electrical performance. Plates range in size up to 18 by 24 inches with channel depth to .050 inches. Channels can be etched on both sides of the plate. Tolerances of .003 inches in depth and width can be achieved in Titanium and 316 Stainless Steel. In addition, the photo etching process offers fuel cell designers unique time-saving and cost advantages. Since no expensive tooling or mold making is required, plates are manufactured to customer specification from drawing to finished part in just three weeks. Flow field adjustments require only a new phototool. Tooling typically costs just $400. These production processes are extremely desirable in the design and prototype stage of fuel cell development.

Download a copy of our Precision Engineered Parts Capabilities Brochure (1.7Mb pdf).