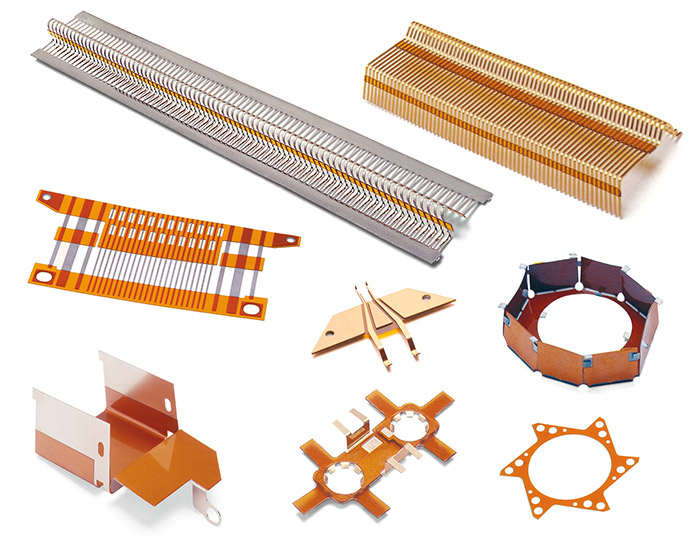

Laminating Precision Parts With Polyimide Film for Insulation & Spacing

Plymouth, MA….When a dielectric is required to maintain accurate finger spacing or for insulation, Tech-Etch can laminate materials such as polyimide. Polyimide can be die-cut and directly bonded in place or full sheet laminated and then photo etched for extremely accurate positioning. Parts can be formed after lamination of insulation. Tech-Etch also photo etches polyimide film into flat parts including non-conductive washers, screens, gaskets, insulation layers and liners, as well as haptics for intraocular lenses used in cataract surgery. For flexible circuits, the coverlay is the insulating layer of polyimide placed over the exposed conductors. It is typically constructed of a pre-cut piece of polyimide film laminated over the conductors using either acrylic or epoxy adhesive. Polyimide’s material characteristics make it ideal for corrosive environments. It also exhibits excellent physical, chemical and electrical properties over a wide temperature range. Tech-Etch offers complete prototype to production facilities for etching extremely intricate parts from polyimide film.

Download a Capabilities Brochure.