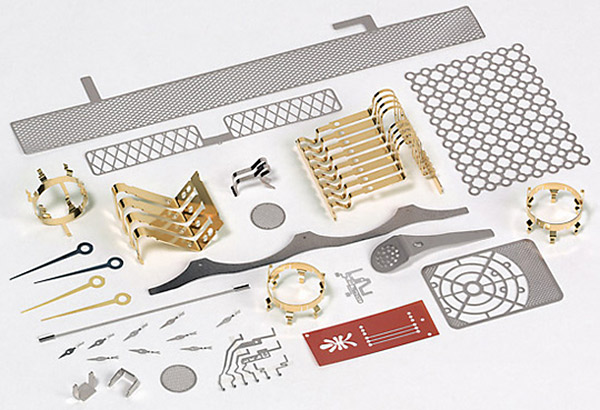

Photo Etched Medical Parts

Plymouth, MA….With its recent development of the processes of coating carbon based conductive corrosion resistant coatings and the production etching of medical parts made from Nitinol, Tech-Etch has added to its manufacturing of light-gauge, metal parts for the medical industry through photo chemical etching, a process that produces intricate components with close tolerances. Tech-Etch is setting industry standards fabricating electronics connectors, haptics for intraocular lens, implantables, reconstructive mesh, filters, XRay collimators, battery grids, needles, blade blanks, vascular stiffeners, ultrasound transducer circuits, vascular closures, encoders, masks, lead frames, springs, strain gauges, EMI shields and more. In addition to Nitinol, metals that can be etched include, Titanium, Tungsten, Molybdenum, Copper Alloys, Beryllium Copper, Stainless Steels, Aluminum, Elgiloy, Niobium, Nickel Alloys, Silver, and Spring Steels, plus polyimide film. These materials have characteristics attractive to the medical industry. Parts range in thickness from .0005” and up. Formed parts are manufactured by combining photo etching for blanking with inexpensive or universal tooling for forming. While providing quick turnaround and low tooling costs, this method produces burr-free parts with intricate and complex shapes. Designs can be proved in preproduction quantities without having to commit to expensive tooling. Laminating, plating, heat treating, and assembly are available in house.

Download a copy of our Precision Engineered Parts Capabilities Brochure (1.7Mb pdf).