Photoetched Specialty Materials

Properties

TUNGSTEN & MOLYBDENUM

TUNGSTEN and MOLYBDENUM are difficult to etch refractory materials used for high-temperature, corrosion resistant applications.

TITANIUM

TITANIUM is strong, light weight and highly resistant to corrosion. Its strength is comparable to 304 stainless steel and it is used for human implants.

ELGILOY

ELGILOY is typically used when requirements call for a material that is highly corrosion resistant with high fatigue strength. It is used for human implants.

KAPTON®

KAPTON is a polyimide film that exhibits good physical, chemical and electrical properties over a wide temperature range. Its electrical and chemical resistance properties are excellent even at unusually high temperatures.

® Kapton is a DuPont registered trademark.

NIOBIUM (Columbium)

NIOBIUM is a light weight refractive material with excellent high temperature corrosion resistance. It is ductile and easily formed.

NITINOL (NiTi)

NITINOL is a shape memory alloy. Its unique characteristics allow it to return to a predetermined shape after undergoing deformation. NITINOL has excellent biocompatibility, good spring characteristics and high corrosion resistance.

Specialty Materials

Tungsten

Molybdenum

Niobium

Titanium

Elgiloy

Kapton®

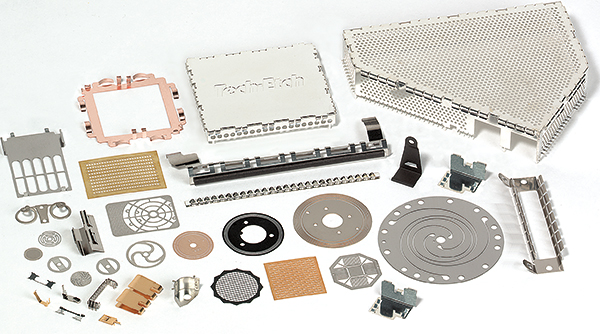

Tech-Etch specializes in photoetching parts from difficult to etch specialty materials, such as Elgiloy, Titanium and Kapton®, which have material characteristics attractive to the medical industry for implants, springs, cathodes, blades, and stents. Parts can be made from metals as thin as .0005″.

Tech-Etch also photoetches parts from other metals such as Copper Alloys, Tungsten, Molybdenum, Stainless Steels, Aluminum, Nickel Alloys and Spring Steels. Photoetching offers the flexibility of manufacturing prototype quantities to large production runs while maintaining tight tolerance without the high cost and long lead times associated with stamping.

Formed parts are manufactured by combining photoetching, used for blanking, with inexpensive or universal tooling, used for forming. Parts can also be etched to 1/2 of their depth for hand forming. Heat treatment is available to enhance spring qualities.

In addition to photoetching, Tech-Etch offers a wide variety of in-house capabilities including laser cutting for thicker materials, forming, laminating, and stamping.

A Total Capability

In addition to photoetching and laser cutting, Tech-Etch offers a wide variety of capabilities including forming, laminating, stamping, heat treating, and plating, plus flexible circuits and RFI/EMI shielding products.

Download the Photoetching and Laser Machining Data Sheet PDF (42K)

Download a copy of our Precision Engineered Parts Capabilities Brochure (1.7Mb pdf).