Photoetching Flat Parts From Polyimide Film

Photoetching Flat Parts From Polyimide Film

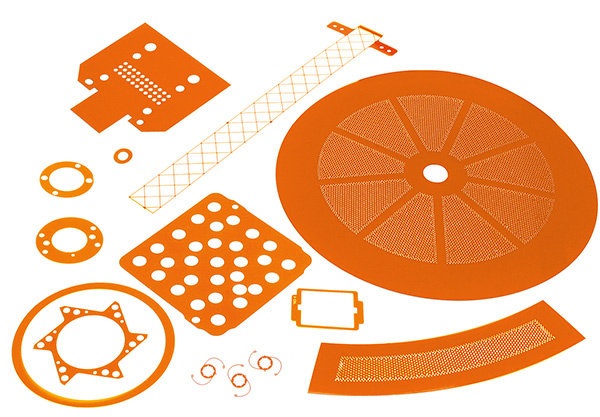

Plymouth, MA….Tech-Etch photo etches polyimide film into flat parts including non-conductive washers, screens, gaskets, insulation layers and liners, as well as haptics for intraocular lenses used in cataract surgery. Polyimide has material characteristics that make it attractive for this medical procedure, in addition to providing the advantages of a 3-piece IOL. Optimal for foldable IOL silicone or acrylic lenses, polyimide offers flexibility comparable to polypropylene and PMMA haptics, with greater tensile strength, and superior shape memory. Since polyimide is safe for implant, additional medical applications can be derived from its shape retention spring properties. Photo etching offers low tooling costs, very fast turnarounds and allows rapid design changes. It also enables etched bend lines on the part for 3D forming. Parts are commonly made from .001″, .002″, .003″, and .005″ Dupont KAPTON® or other polyimide films. Polyimide’s material characteristics make it ideal for corrosive environments. It also exhibits excellent physical, chemical and electrical properties over a wide temperature range. Tech-Etch offers complete prototype to production facilities for etching extremely intricate parts from polyimide film. (KAPTON® is a DuPont registered trademark.)

Download a copy of our Precision Engineered Parts Capabilities Brochure (1.7Mb pdf).