Since our founding in 1964, Tech Etch has evolved from a small photo chemical etching business into a leading manufacturer of precision-engineered components, serving diverse industries such as aerospace, medical devices, electronics, and telecommunications. This timeline showcases our significant milestones, reflecting our commitment to quality, community, and continuous improvement. Explore the rich history that has shaped Tech Etch into the industry leader it is today.

1964

August 21

- George Keeler formed G.E. Keeler Inc. to purchase the assets and business of T.J. Edwards Co. in Jamaica Plain (Boston), which is the present surviving corporation.

- The name of the corporation was changed to T.J. Edwards Inc., an engraving company primarily making stitch marking dies for the shoe industry and nameplates by etching and anodizing. Later, nameplates were discontinued, focusing solely on marking dies and machines for the shoe industry.

1966

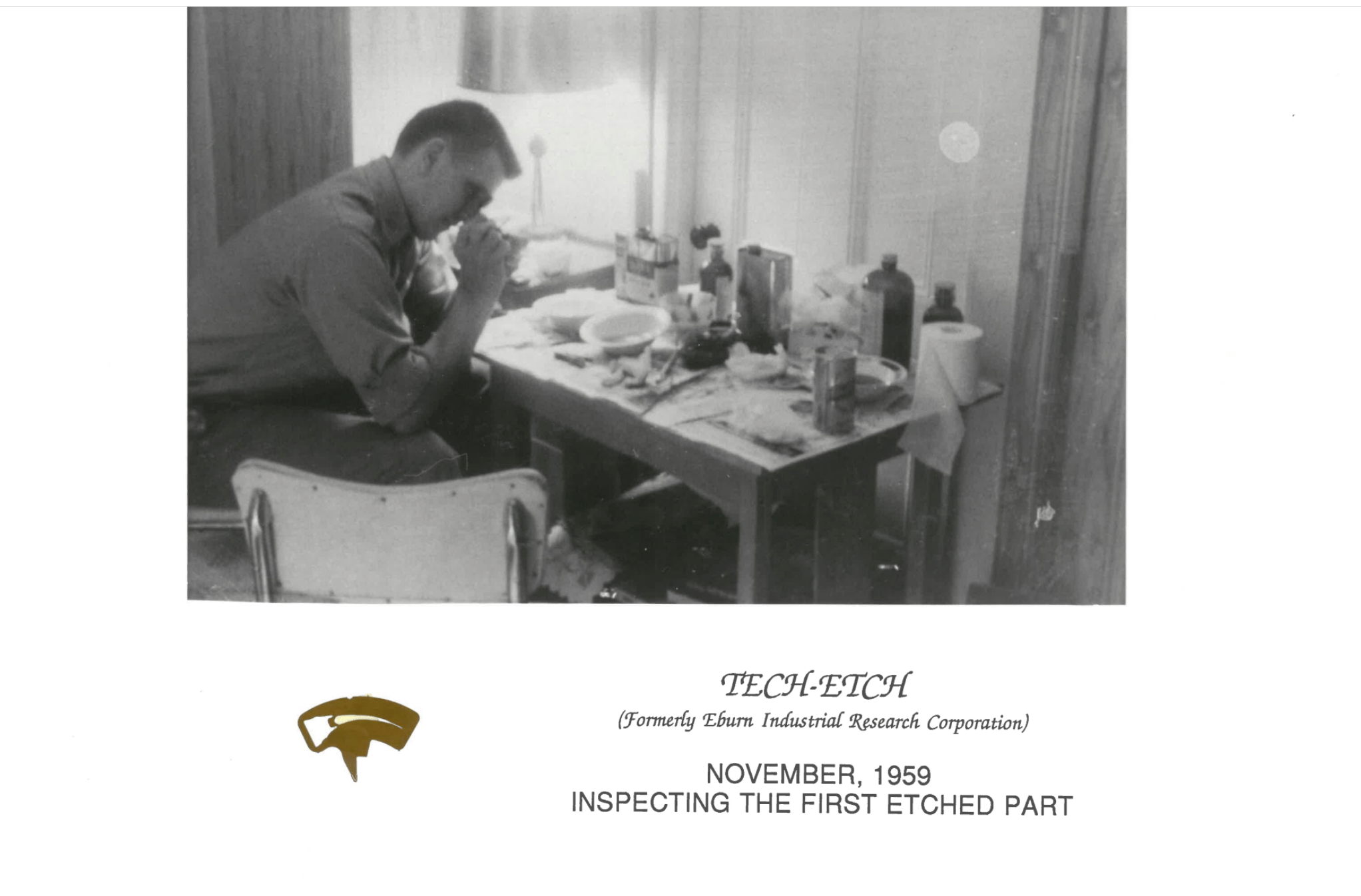

- George Keeler purchased the assets and business of Eburn Industrial Research Company in Hingham, MA, producing precision metal parts by photo etching. This acquisition marked the beginning of Tech-Etch’s journey in the high-precision metal parts industry.

1970

- T.J. Edwards Inc. transferred its nameplate business to a plant in Brockton, operating under the Tech-Etch name.

1972

Drawing of Jim Kenworthy, drawn by Employee Owner Karen Bitterman

- In 1972 Jim Kenworthy, the R&D Manager, created a formula for etching Kapton. This allowed Tech-Etch to enter the flexible printed circuit market.

- Jim Kenworthy worked at Tech-Etch almost since the start and retired in 2004.

1975

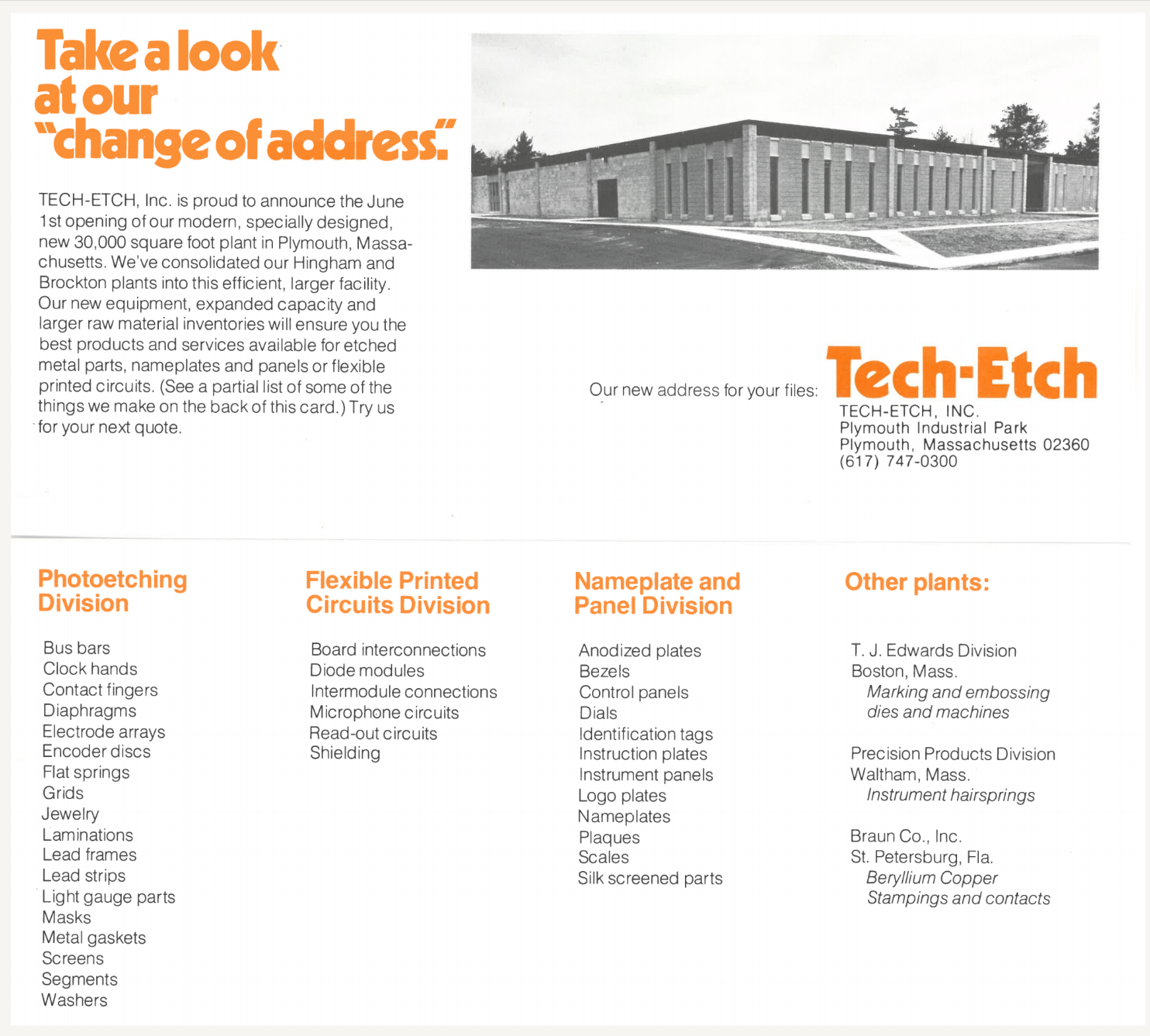

June

June

- Tech-Etch moved its Hingham and Brockton operations to a new 32,000 sq ft plant in Plymouth.

- Braun Co., a company located in St. Petersburg, FL, specializing in manufacturing formed parts from beryllium copper, primarily used as RFI shielding gaskets, was purchased by George Keeler.

1977

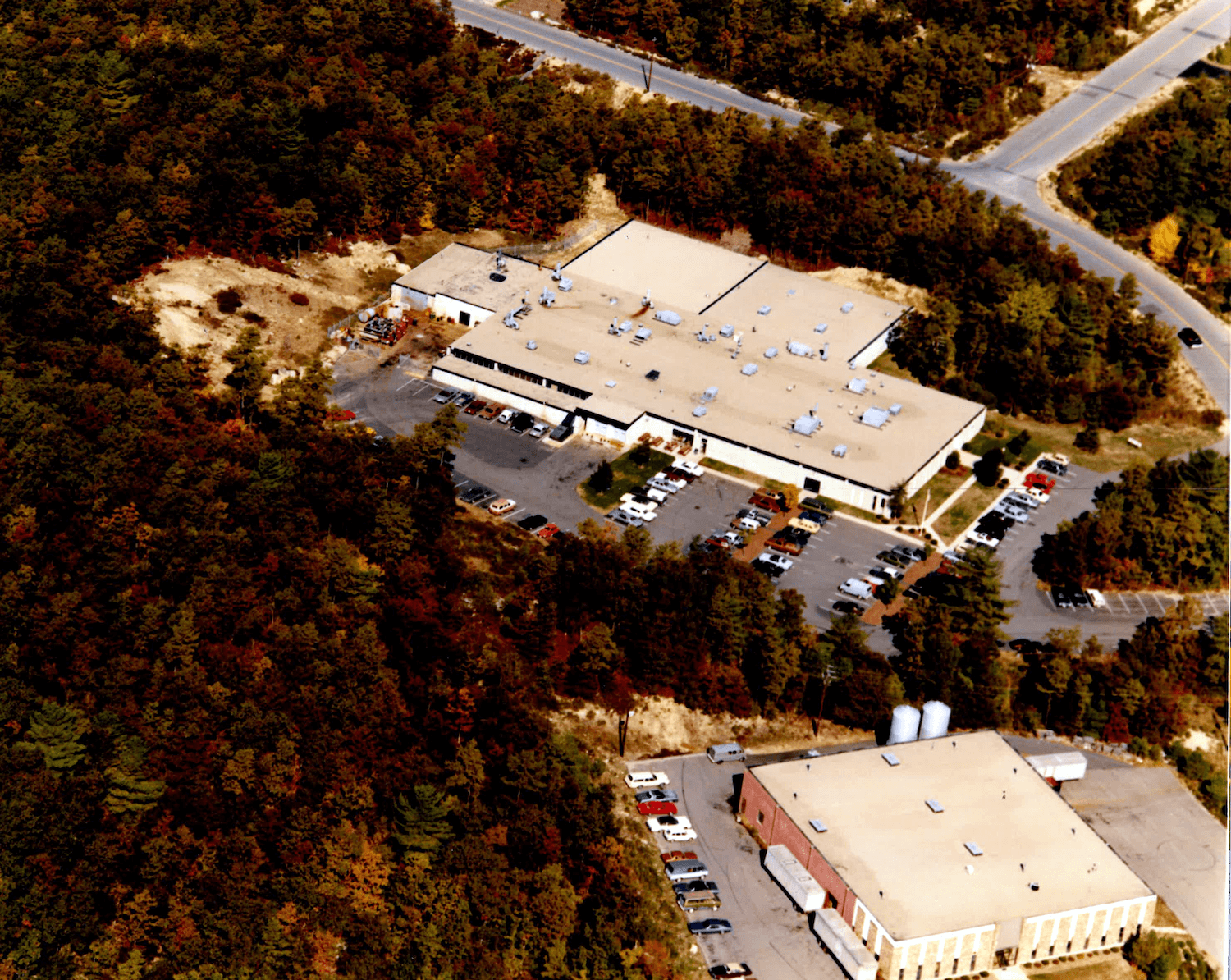

Original Plymouth location today

- Braun Co. Inc. merged into Tech-Etch and moved from St. Petersburg to Plymouth.

- Tech-Etch discontinued its nameplate business to focus on its core competencies and expanding markets.

1978

- Tech-Etch expanded its facilities with a 7,900 sq ft addition, dedicated to a tool room and stamping presses, enhancing its manufacturing capabilities.

1979

Plymouth post expansion in 1979

- Tech-Etch further expanded its facilities with a 7,400 sq ft addition, increasing its production capacity.

1982

Plymouth post expansion in 1979

- Tech-Etch added a 5,600 sq ft addition to bring electroplating of shielding gaskets in-house, improving quality control and efficiency.

1985

- Tech-Etch acquired the assets and business of EMC Shielding Inc. in Garden Grove, CA. This acquisition, which included complementary shielding products, led to the creation of Tech-Etch’s EMC Shielding Division.

1989

- Tech-Etch leased the remaining 12,000 sq ft of the Fall River building and relocated the EMC Shielding Division from Garden Grove to Fall River, consolidating operations and enhancing efficiency.

1990

- Tech-Etch formed a subsidiary corporation, Tech-Etch/Merel Inc., to acquire the assets and business of Merel Company in Gardena, CA. Merel was a west coast competitor specializing in photoetching metal parts and laser cutting.

1992

- The T.J. Edwards Co. Division was sold, marking a strategic shift in Tech-Etch’s business focus.

1994

- Tech-Etch expanded its Plymouth facility with an 18,000 sq ft addition for manufacturing.

- A 7,000 sq ft addition was also made to provide office and engineering space, supporting growing operations.

1997

- An additional 5,000 sq ft was added to the Plymouth plant, creating a dedicated employee lunch room and enhancing workplace amenities.

- Obtained first ISO Quality Management System Certification.

1999

- Tech-Etch dissolved Tech-Etch/Merel Inc., consolidating its assets and business in Plymouth.

- Initiated demolition and reconstruction of 13,000 sq ft of existing space to modernize facilities for wet processes, alongside the construction of a new 25,000 sq ft addition.

- Achieved 30% Employee Stock Ownership Plan (ESOP), increasing employee ownership and engagement.

2003

- Acquired the assets of Arc Technologies, Inc., introducing the manufacturing capabilities of Fabric over Foam shielding products and diversifying Tech-Etch's product offerings.

2006

- Purchased assets from Innovex in Litchfield, MN, expanding chemical etching operations and enhancing production capabilities.

2008

- Made a significant $1M donation to the Beth Israel Deaconess Imaging Center, demonstrating Tech-Etch’s commitment to community support and corporate social responsibility.

2014

- Expanded the Plymouth location by 43,000 sq ft, creating the metal room and significantly increasing production capacity and operational efficiency.

2014

- Tech Etch proudly celebrated its 50th anniversary, marking half a century of innovation, growth, and excellence in the manufacturing industry.

2018

- Achieved 100% Employee Stock Ownership Plan (ESOP), fully transferring ownership to employees and reinforcing a culture of ownership and engagement.

2018

January 28

- Founder George Keeler retired, marking the end of an era and the beginning of a new leadership chapter for Tech-Etch.

2018

June 18

- Rich Cammarano became President and CEO, leading Tech-Etch into a new phase of growth and innovation.

2021

- Rebranded to Tech Etch, reflecting a modern identity and forward-looking vision.

2021

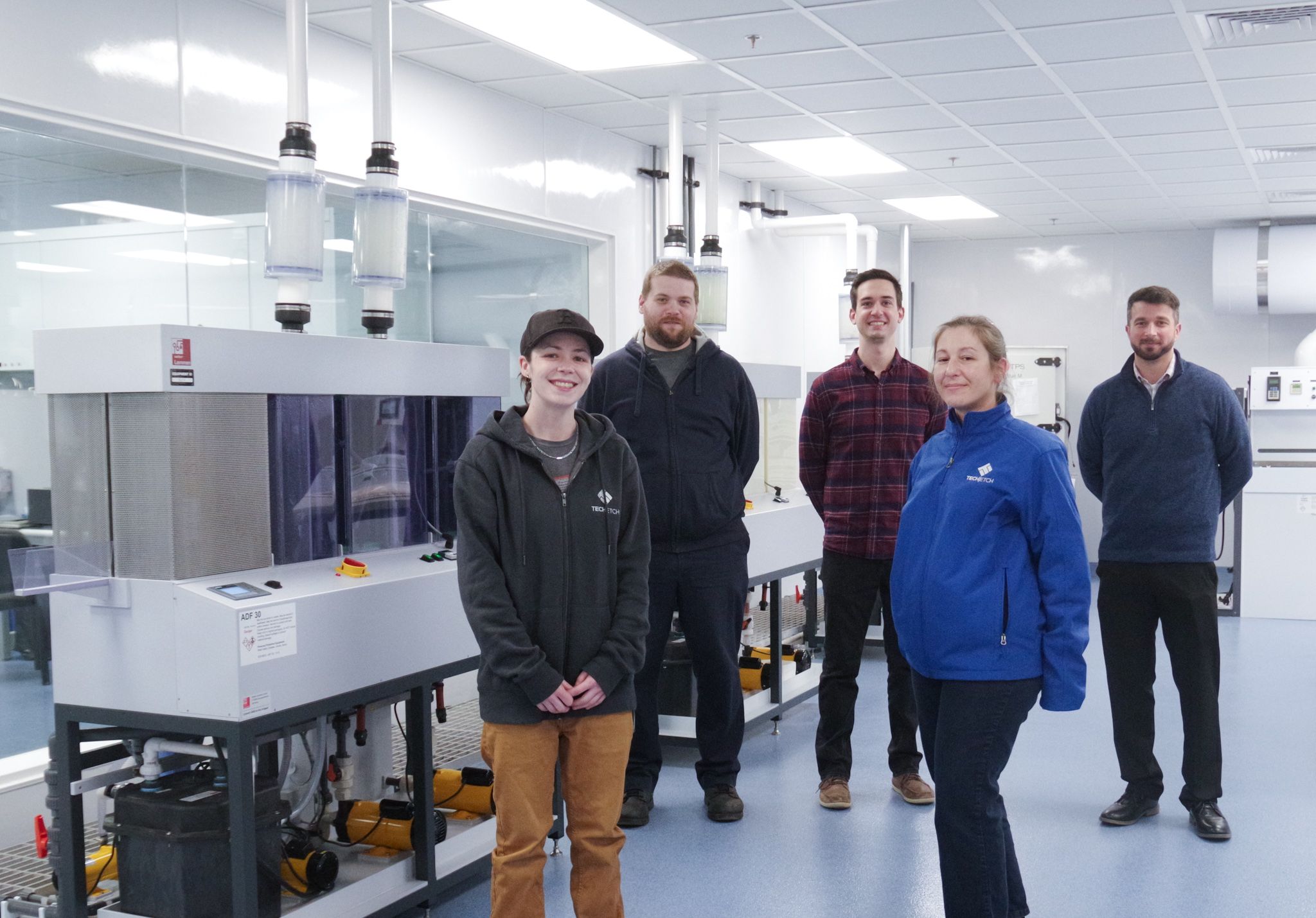

- Established the Innovation Center and Logistics Center, furthering Tech-Etch’s commitment to innovation and operational excellence.

- Obtained AS9100 Certification at all three facilities, underscoring a commitment to quality and excellence in aerospace and defense.

- Tech Etch Honored with Edwards Lifesciences Award.

2022

- Named New England ESOP Company of the Year, recognizing the company’s success and leadership as an employee-owned business.

- Recognized as one of Plymouth & Cape’s Best Places to Work, highlighting Tech Etch’s commitment to its employees and workplace excellence.

- Obtained ISO 13485:2016 Certification at its Plymouth and Litchfield locations, affirming its quality management system for medical devices.

- Tech Etch Honored with Edwards Lifesciences Award for the second time.

2023

ESOP Annual Award for Communications Excellence

- Tech Etch wins Annual Award for Communications Excellence (AACE) from the ESOP Association.

- Honored as Manufacturer of the Year, celebrating Tech Etch’s industry leadership and achievements.

- ISO 13485 Certification at our Litchfield location.

- Tech Etch becomes three time award winner of the Edwards Lifesciences Award.

2024

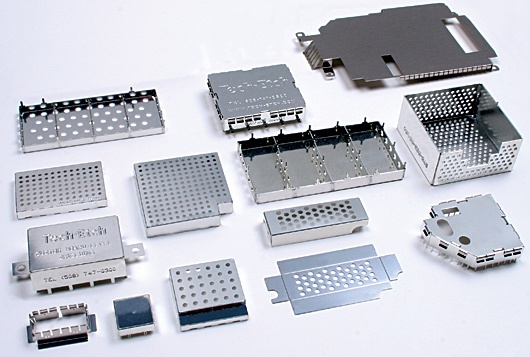

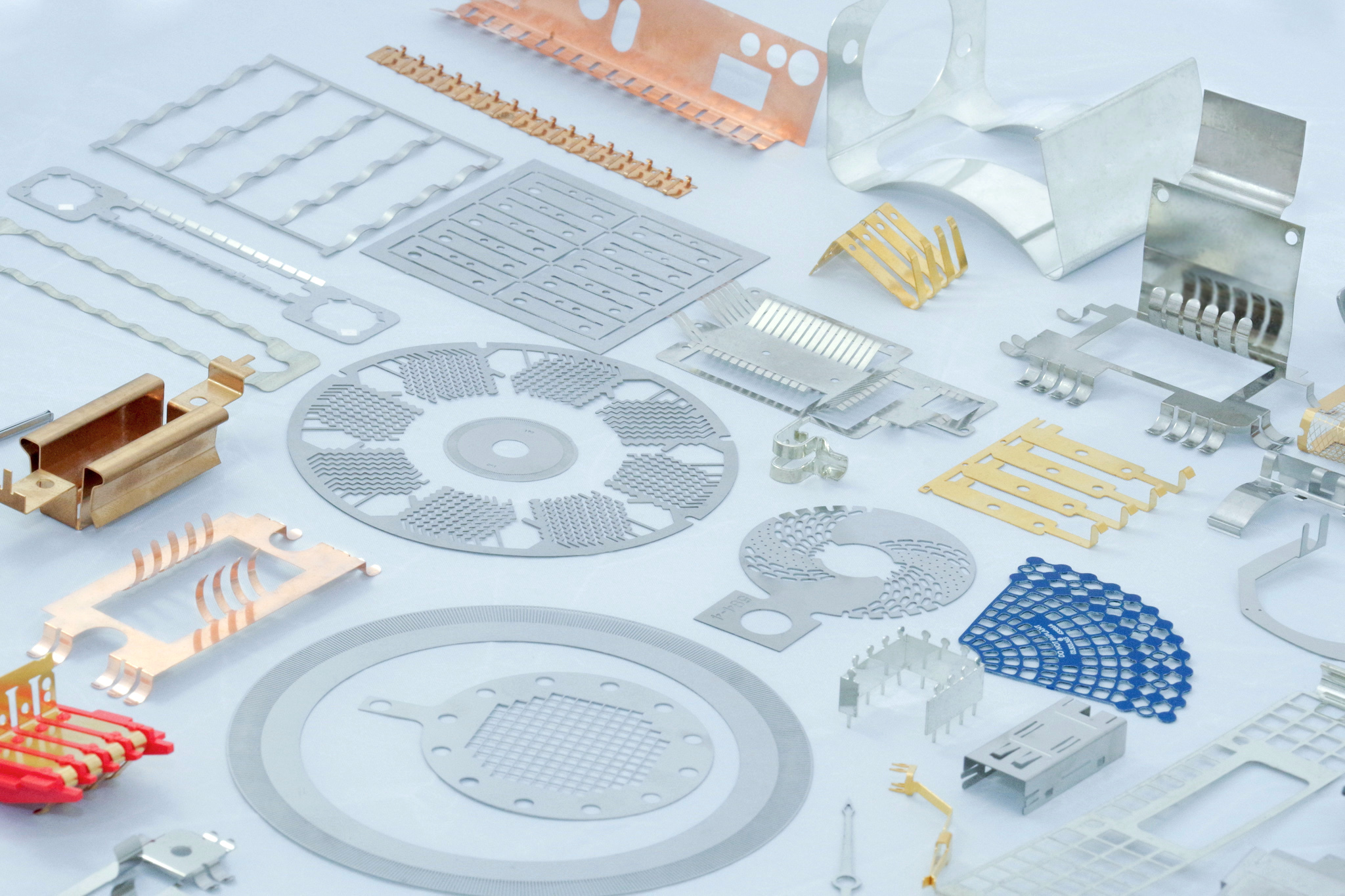

- Tech Etch has six decades of experience and expertise specializing in manufacturing precision-engineered thin metal components, flexible printed circuits, and EMI/RFI shielding, across three locations in the United States (Plymouth, MA, Fall River, MA, and Litchfield, MN). Our commitment to excellence begins with employee-owners who provide world-class services and innovative comprehensive solutions that enhance lives globally. We partner with leading global customers in the aerospace, alternative energy, military, medical, telecommunication, and electronics industries that have precise designs and demanding regulatory requirements. Our solutions ensure unmatched precision, quality, and attention to detail in every project, every time.

- Rich Cammarano became President for the New England Chapter ESOP Association.